Business Process for Arden Trucking Domestic

From UG

Contents |

Intro

Arden Trucking Domestic is not NATP but it would help in designing NATP Business Process because it probably is just a simpler version of NATP.

It is also called Arden Trucking Project (ATP) as opposed to New Arden Trucking Project (NATP)

Summary

Elizabeth Arden Trucking domestic is planned by Traffic planner at EA. Traffic planner tells Jaguar what truck company that they want to use, where they want to the trucker to pick up and deliver shipments, and what the contents of the shipments are.

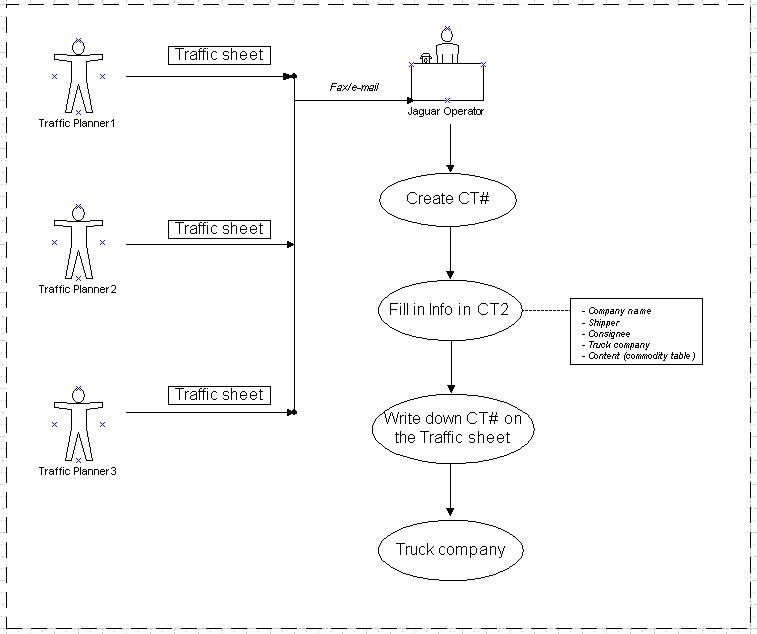

Use case 1. Create CT from Traffic sheets

Normal Flow of Events

1) Traffic planner from EA traffic department sends traffic sheets to Jaguar

2) Jaguar operator looks at all traffic sheets and combines the same case together (same shippers and consignees)

NOTE: This is done per day

3) Jaguar operator creates CT# and enter information into CT2 such as Company name, shipper, consignee, truck company, content (commodity table)...etc

4) Jaguar operator writes down CT# that was created on Traffic sheet for a reference

5) Jaguar operator fax/e-mail traffic sheet to truck company

See #Figure 1. Create CT from Traffic sheets

Figure 1. Create CT from Traffic sheets

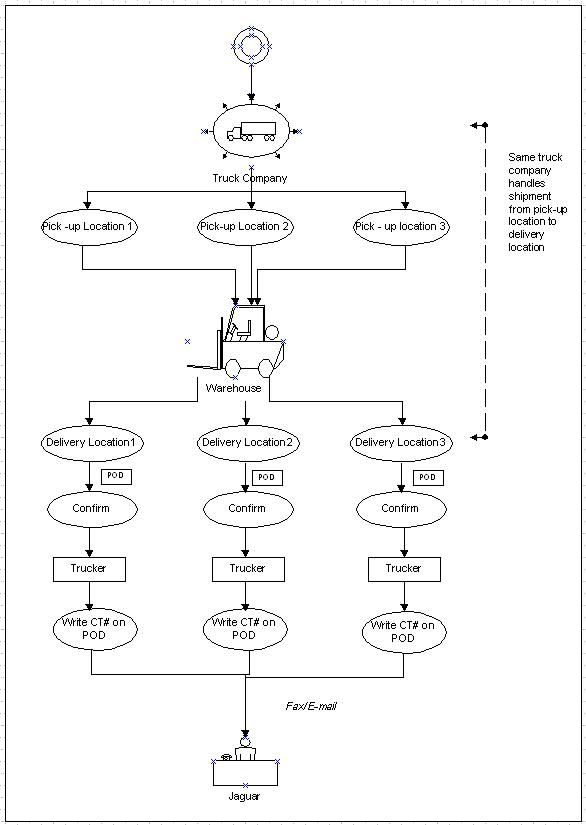

Use case 2a. Direct Pick-up and deliver (NJ, NY, and CT)

Normal Flow of Events

1) Truck company received Traffic sheets

2) Trucker goes to pick up shipment from shipper(s); this can be many truckers to pick up shipment from many other shippers in tri-states area

3) Trucker unloads shipments at the warehouse to consolidate

4) Trucker loads shipments and delivers shipment to consignees

5) Consignees receive shipments and give confirmation POD (proof of delivery) document to Trucker

6) Trucker writes CT# reference on POD (CT# must be matched to the CT# that was created by Jaguar operator)

7) Trucker fax/e-mail POD to Jaguar company

NOTE: This case will be billed from pick-up location to delivery location for truck movement

See #Figure 2a. Direct Pick-up and deliver (NJ, NY, and CT)

Figure 2a. Direct Pick-up and deliver (NJ, NY, and CT)

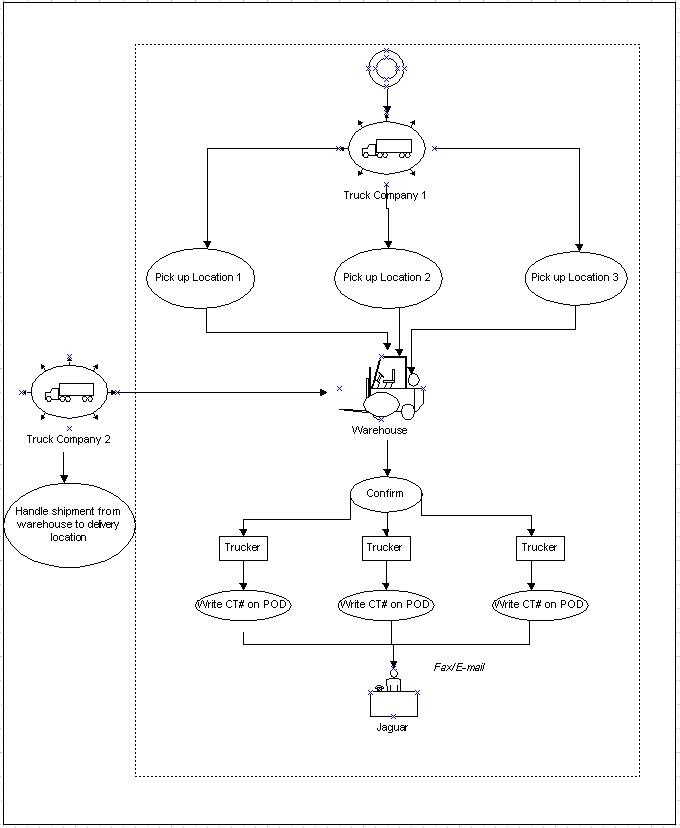

Use case 2b. Consol Pick-up and deliver (VA)

Normal Flow of Events

1) Truck company received Traffic sheets

2) Trucker goes to pick up shipment from shipper(s); this can be many truckers to pick up shipment from many other shippers in tri-states area

3) Trucker unloads shipments at the warehouse to consolidate

3a) A different truck company will handle shipments from the warehouse to consignee

NOTE: Jaguar handles shipments from shippers to warehouse ONLY

4) Shipments get received and confirmed by warehouse people

5) Warehouse people give POD (proof of delivery) to trucker

6) Trucker writes CT# reference on POD (CT# must be matched to the CT# that was created by Jaguar operator)

7) Trucker fax/e-mail POD to Jaguar company

NOTE: This case will be billed from pick-up location to warehouse location for truck movement

See #Figure 2b. Consol Pick-up and deliver (VA)

Figure 2b. Consol Pick-up and deliver (VA)

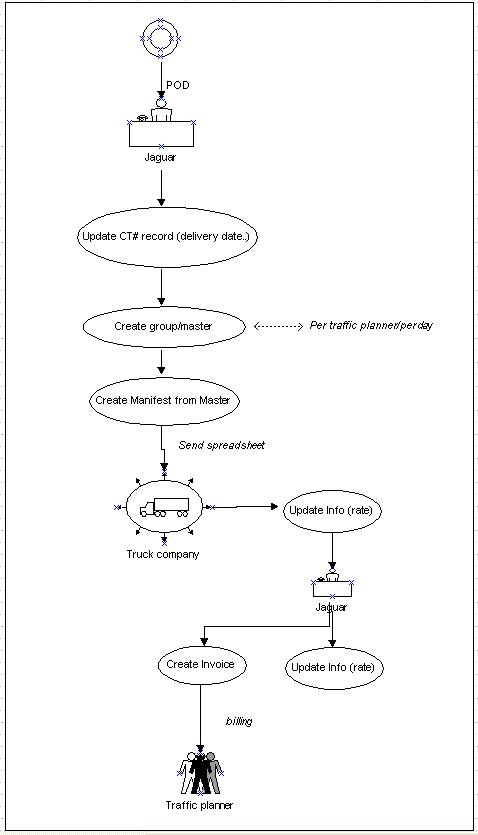

Use case 3. Bill to truck planner

Normal Flow of Events

1) Jaguar receives POD from Trucker via fax/e-mail

2) Operator updates CT record with delivery date

3) Operator creates CT groups. One group per traffic planner per day. There are 3 planners.

4) Operator creates a master on top of every group

5) Operator creates Trucking Billing Manifest from each master (this can be up to 3 spreadsheet per day; 3 traffic planners)

6) Operator updates rate information on the billing manifest

7) Operator sends the billing manifest spreadsheet to truck company

8) Truck company updates information and sends it back to Jaguar

9) Jaguar adjust number (adding margin) in order to bill the traffic planner(s);

10) Operator creates one pdf invoice and attaches all billing manifests above and sends to the client

See #Figure 3. Bill to truck planner

Figure 3. Bill to truck planner