Use Cases for EDI to TMS

From UG

Contents |

Business story

July 22

Shipper Mary with Jackel creates 1 new CT record (# 11111) shipping from her NJ warehouse, Gannet Warehouse at 58 Executive Drive in Edison, NJ. She only has 1 pallet ready and would like to get this off of her warehouse dock so her warehouse can continue with their monthly inventory stock report. Now at the same shipper Harry with Princeton Label creates 1 new CT record (# 11145) shipping from his NJ warehouse, Princeton Labels & Packaging Inc at 1226 Route 130 in Robbinsville, NJ. He has about 15 pallets that are ready to ship today and hopes that CEI Roanoke will approve this PO/SKU to ship.

...later that day...

Shipper Ed with Rexam creates 1 new CT record (# 11200) shipping from his CT warehouse, Rexam at 60 Electric Avenue in Thomston, CT and he also has only 1 pallet that is ready to ship'

...even later that day...

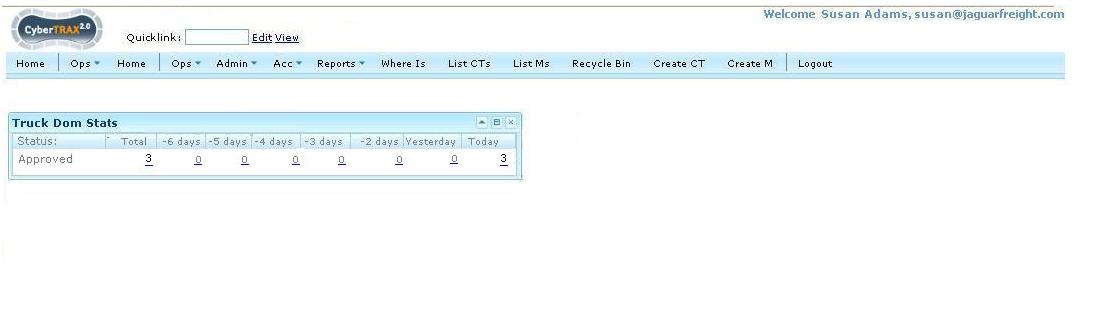

2 separate Arden planners approve these 3 CT records at the same time (# 11111, 11145 & 11200) and now Jag operator Susan checks her TDS dashboard to find these 3 approved shipments

This needs to reflect typical and some exceptional workflows

- 3 CTs get approved

- CT2 sends data to TMS

- Jag oper discovers new approved CTs (how?)

- a) Jag oper manually processes CT

- updates

- docs

- etc

- b) Jag oper uses optimization to handle CT

- updates

- docs

- etc

Use Cases

Jaguar Discovers Approved CTs

Figure 1

Jaguar operator logs into CT2 internal application to find 3 new "Approved" CT records on their TDS dashboard.

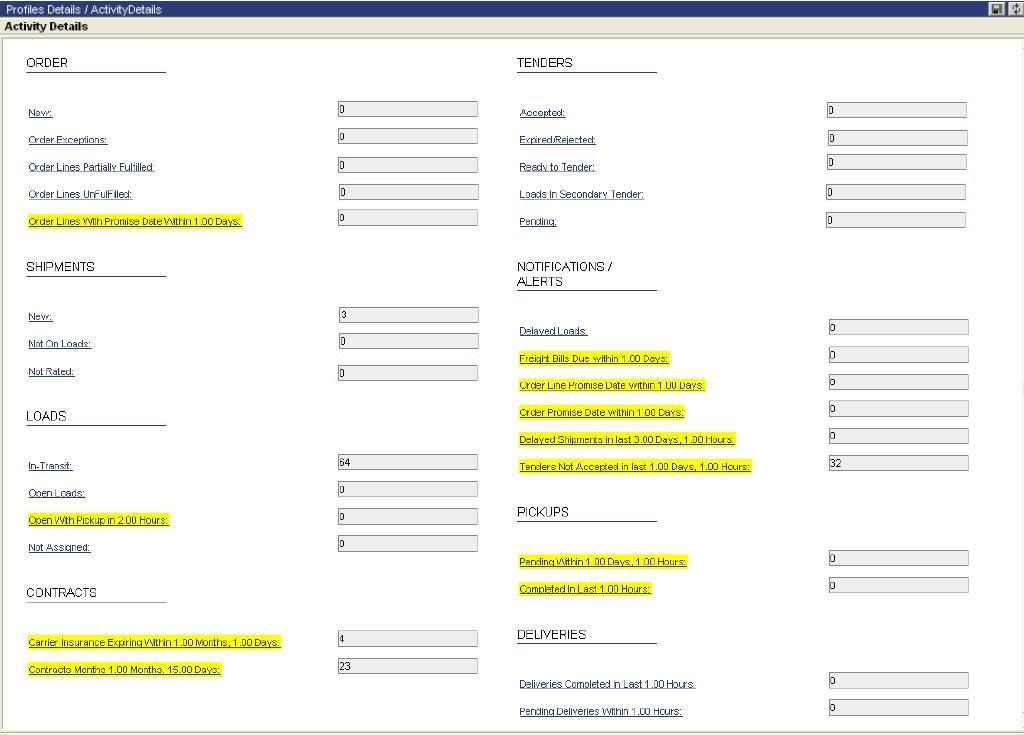

Jaguar Operator uses TMS

Figure 2

Jaguar operator logs onto the TMS system, goes into the Main Menu, > Activity Summaries > Activity Details to find their are new shipments listed. (These are the same "Approved" CT records that are on their TDS dashboard on the internal app).

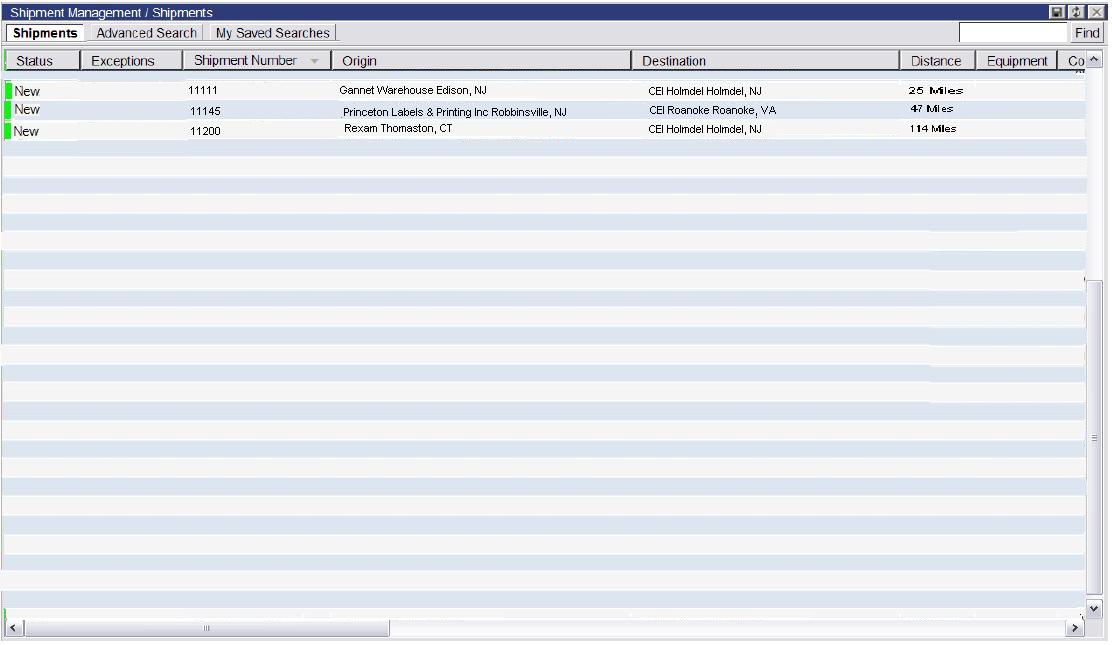

Figure 3

Jag operator clicks on the number of new shipments (3) to review for them to decide who they would like to arrange for the pickup.

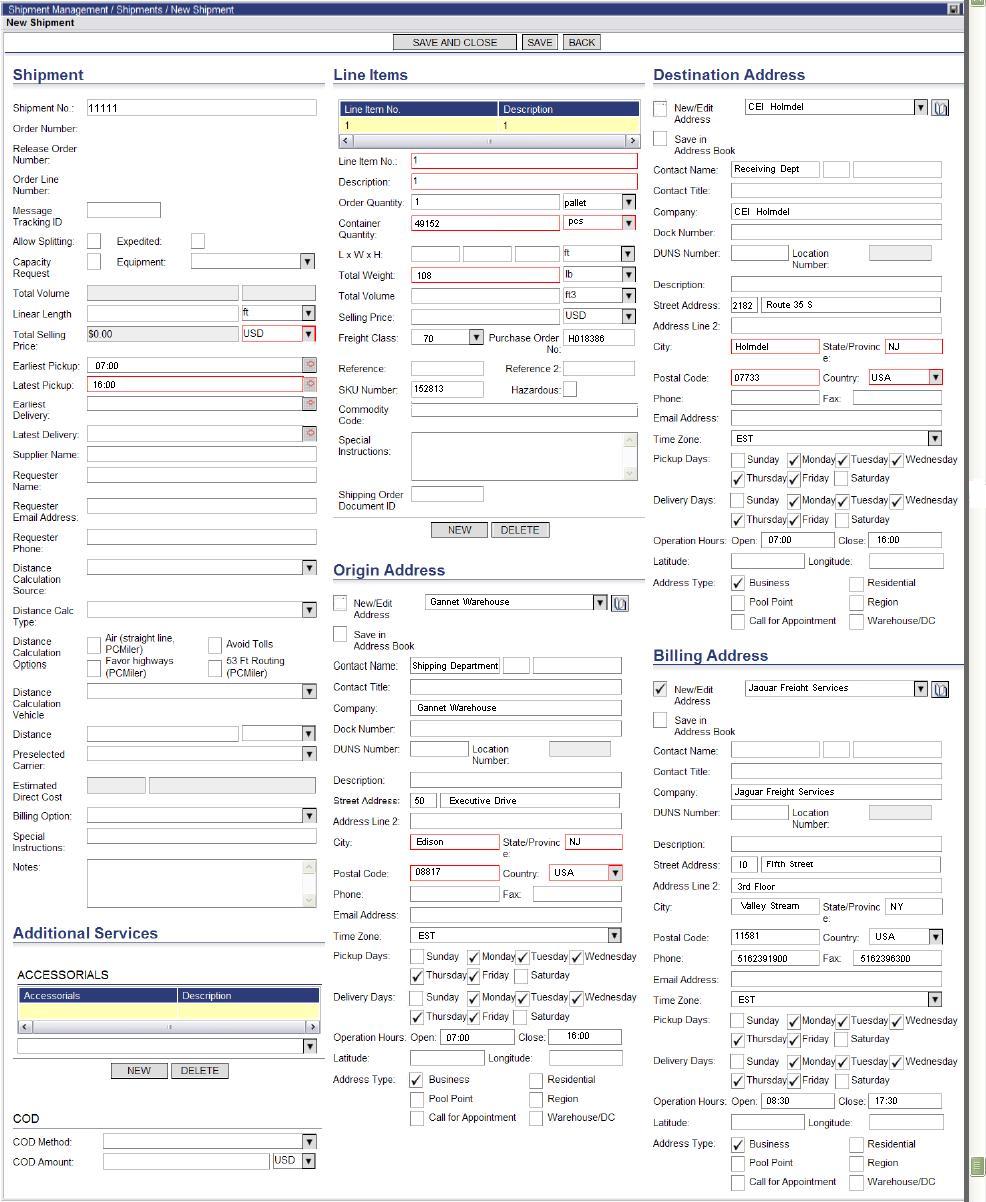

Figure 4

Jag operator looks at the first CT record # 11111.

Figure 6

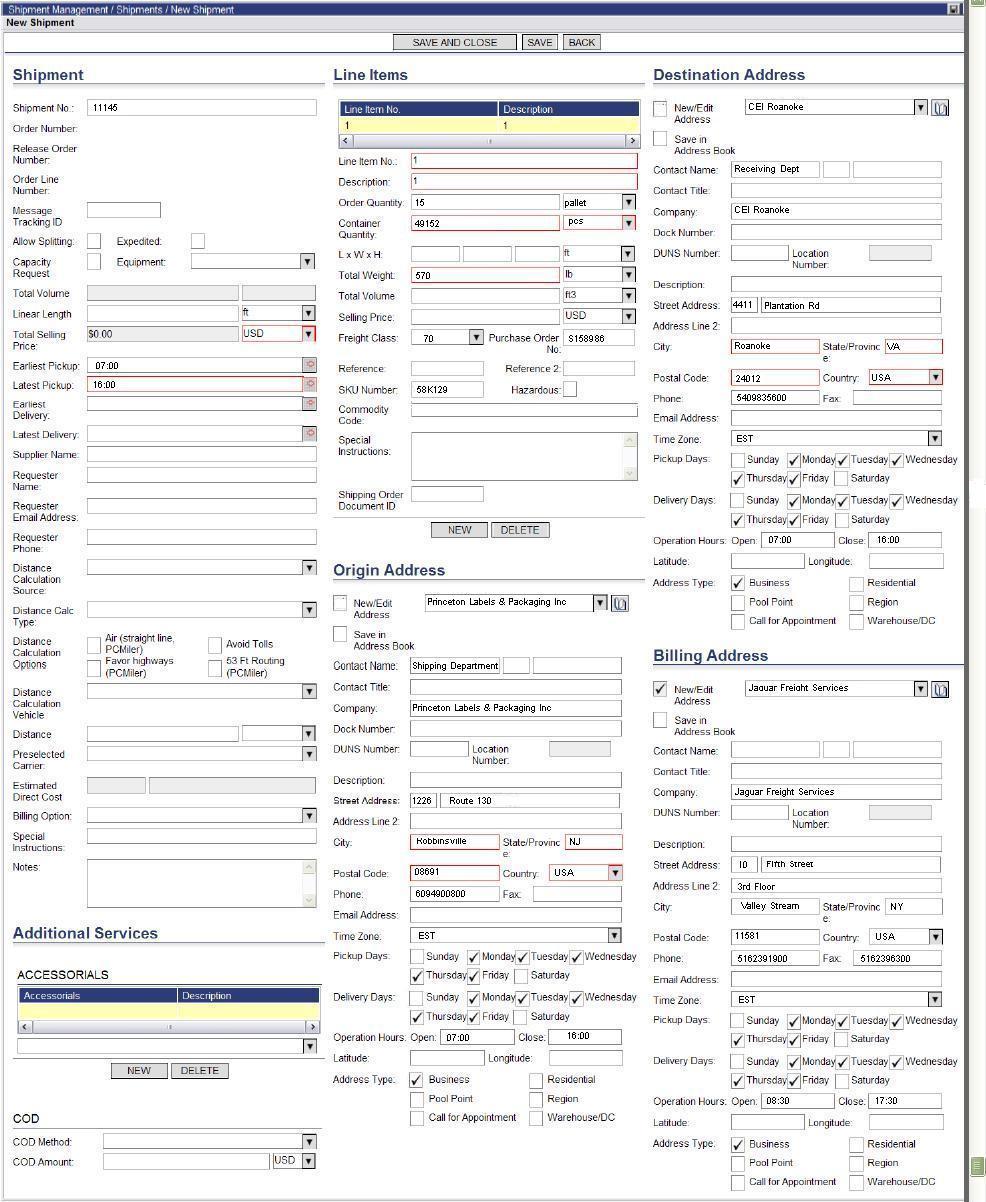

Jag operator looks at the second CT record 11145.

Figure 7

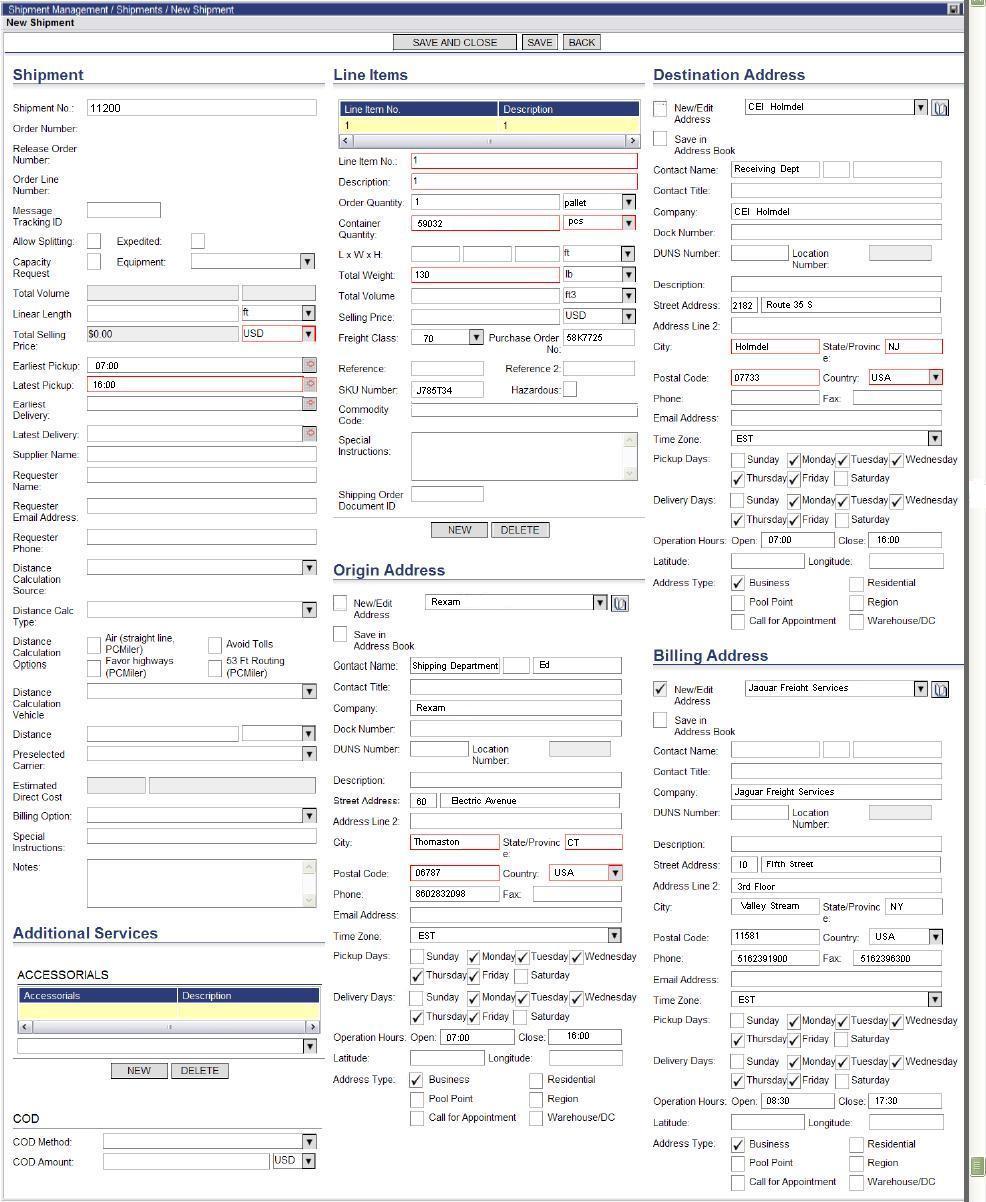

Jag operator looks at the third CT record 11200.

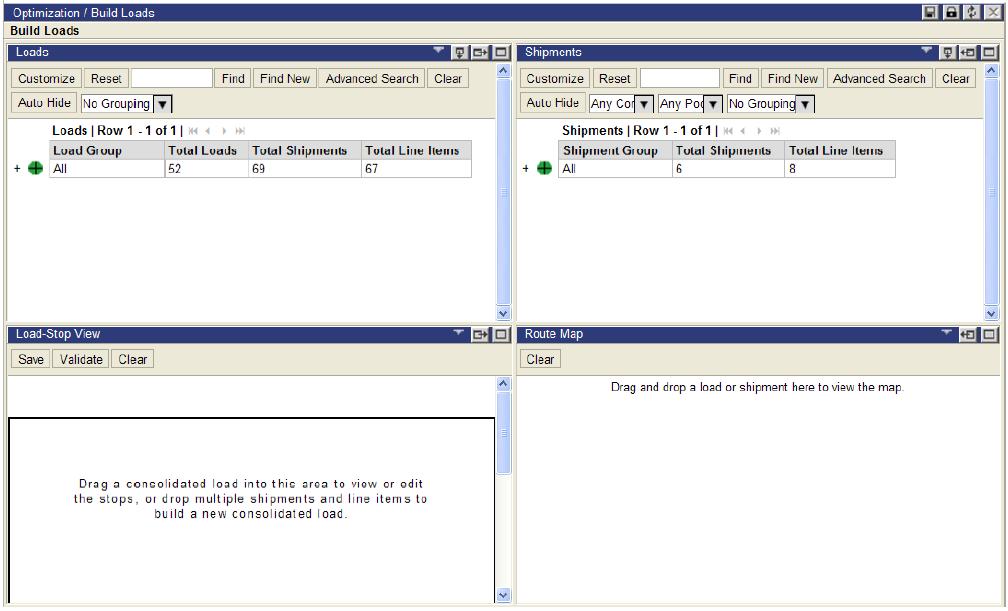

Optimization Process

Through TMS, Jag operator has two options on how to handle these 3 approved shipments. They can have either TMS route them based upon certain criteria from inside the transportation manager which looks at the carrier contracts against the route guides or they can manually route them by way of building a load.

Jag operator selects trucker

Jag operator tenders the load to Jewels Trucking, TMS transits this information to the pickup truckers system and waits for their acceptance or rejection.

Trucker accepts

1) Trucker confirms to TMS that they accept the shipment.

1a) TMS receives this and sends the information back to Jaguar and automatically updates the CT records with the pickup trucking companies name.

2) Trucker updates his system with an estimated pickup date.

2a) Truckers system sends that information to TMS, then TMS sends the information back to Jaguar and automatically updates the CT records with the estimated pickup date.

Trucker Picks up

1) Trucker pickups the shipments from each of the shippers (trucking company can use many different drivers to pickup within the tri-state area).

2) Trucker unloads the shipments at his warehouse and places them to the side for another carrier to arrange the delivery and updates his system that they are ready (or on hand) for pickup.

NOTE: Jaguar handles 1 of these shipments from the shippers facility to their warehouse ONLY.

2a) Truckers system sends that information to TMS, then TMS sends the information to Jaguar and automatically updates the CT record with the actual pickup date.