Use Cases for EDI to TMS

From UG

Contents |

Business story

This needs to reflect typical and some exceptional workflows

- 3 CTs get approved

- CT2 sends data to TMS

- Jag oper discovers new approved CTs (how?)

- a) Jag oper manually processes CT

- updates

- docs

- etc

- b) Jag oper uses optimization to handle CT

- updates

- docs

- etc

Use Cases

Use case 1. Shipper Creates CT via Web Portal

1) Shipper logs into the web portal to enter all new products that are ready to ship and upon clicking save, they create 1 CT per line item.

2) Planner logs into the web portal to view all new records created by shipper and sets the approval status to "Approved".

NOTE: This is done continuously throughout the day.

3) Jaguar operator logs into CT2 internal application to find these "Approved" CT records on their TDS dashboard.

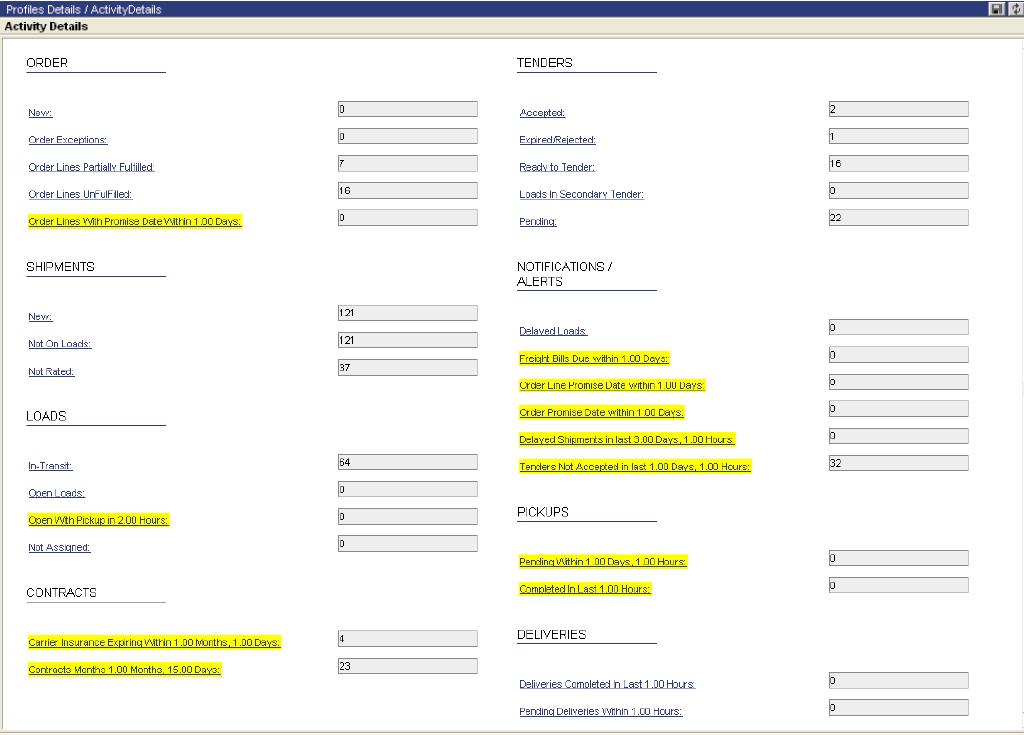

4) As well, Jaguar operator logs onto the TMS system, goes into the Main Menu, > Activity Summaries > Activity Details to find their are new shipments listed. (They are the same "Approved" CT records from internal app).

See Figure 1

4a) Jag operator clicks one New, reviews all of the information for them to decide who they would like to arrange for the pickup.

5) Now through TMS, Jag operator assigns the pickup trucker.

6) Then TMS transits this information to the pickup truckers system and waits for their acceptance or rejection.

Use case 1a. Direct Pickup and delivery (NJ, NY, and CT)

1) Trucking company receives all relevant shipping information (pickup & delivery address, the packaging information - including weight and volume) from TMS.

1a) Trucker confirms to TMS that they accept the shipment.

1b) TMS receives this acceptance, sends the information back to Jaguar and automatically updates the CT records with the pickup trucking companies name.

2) Trucker updates his system with an estimated pickup date.

2a) Truckers system sends that information to TMS, then TMS sends the information back to Jaguar and automatically updates the CT records with the estimated pickup date.

3) Trucker pickups the shipments from each of the shippers (trucking company can use many different drivers to pickup within the tri-state area).

4) Trucker unloads the shipments at his warehouse to consolidate for delivery and updates his system.

4b) Truckers system sends that information to TMS, then TMS sends the information to Jaguar and automatically updates the CT record with the actual pickup date.

5) Trucker now updates his system that the shipments are loaded and are out for delivery.

5a) Jaguar operator goes into TMS to update the estimated delivery date.

5b) Truckers system sends that information to TMS, then TMS sends the information back to Jaguar and automatically updates the CT records with the estimated delivery date.

6) Consignee receives their shipments and gives a confirmation POD (proof of delivery) document to the trucker.

7) Trucker updates his system with the confirmation POD information (Name of who signed for it, date and time) received from the consignee.

7b) Truckers system sends that information to TMS, then TMS sends the information back to Jaguar and automatically updates the CT records with the actual delivery date.

8) Trucker writes the CT# reference on the POD (CT# must match the CT# that was created by shipper user).

9) Trucker faxes/e-mails the POD to Jaguar.

10) Jaguar operator uploads the POD document into the CT record.

Use case 1b. Consol Pick-up and deliver (VA)

1) Trucking company receives all relevant shipping information (pickup & delivery address, the packaging information - including weight and volume) from TMS.

1a) Trucker confirms to TMS that they accept the shipment.

1b) TMS receives this and sends the information back to Jaguar and automatically updates the CT records with the pickup trucking companies name.

2) Trucker updates his system with an estimated pickup date.

2a) Truckers system sends that information to TMS, then TMS sends the information back to Jaguar and automatically updates the CT records with the estimated pickup date.

3) Trucker pickups the shipments from each of the shippers (trucking company can use many different drivers to pickup within the tri-state area).

4) Trucker unloads the shipments at his warehouse and places them to the side for another carrier to arrange the delivery and updates his system that they are ready (or on hand) for pickup.

NOTE: Jaguar handles these shipments from the shipper's to the warehouse ONLY.

4a) Truckers system sends that information to TMS, then TMS sends the information to Jaguar and automatically updates the CT record with the actual pickup date.

5) Delivery trucker now goes in to pick up the shipments, signs a confirmation receipt (which is like a POD) of what he is picking up and gives a copy to the pickup trucker. Pickup trucker updates their system that the shipments were transferred to the delivery trucker accordingly.

5a) Truckers system sends that information to TMS, then TMS sends the information back to Jaguar and automatically updates the CT records with the estimated & actual delivery dates.

6) Pickup trucker takes the signed confirmation receipt, writes the CT# reference on it (CT# must match the CT# that was created by shipper user).

7) Trucker faxes/e-mails the POD to Jaguar.

8) Jaguar operator uploads the POD document into the CT record.