Use Cases for EDI to TMS

From UG

(→Temp) |

(→Milk run From CT1 at A to CT2 at B to delivery point C) |

||

| Line 17: | Line 17: | ||

* Assign pickup/delivery dates (manually?) | * Assign pickup/delivery dates (manually?) | ||

| - | === | + | === Miami to Boston and Atlanta to NY === |

| - | * | + | * CT1: |

| - | * | + | ** from: Miami, FL |

| - | ** | + | ** to: Boston, MA |

| - | * | + | |

| - | * | + | * CT2: |

| + | ** from: Atlanta, GA | ||

| + | ** to: New York, NY | ||

| + | |||

| + | ==== Shipment Import XML ==== | ||

| + | TBD | ||

| + | |||

| + | ==== Optimal route ==== | ||

| + | |||

| + | * Track A: | ||

| + | ** Start: Pick up CT1 in Miami | ||

| + | ** Stop#1: Pick up CT2 in Atlanta | ||

| + | ** Stop#2: Drop off CT2 in New York | ||

| + | ** Finish: Drop off CT1 in Boston | ||

| + | |||

| + | ===== Load Plan XML for Optimal===== | ||

| + | TBD | ||

| + | |||

| + | ==== Non Optimal route ==== | ||

| + | |||

| + | * Track A: | ||

| + | ** Start: Pick up CT1 in Miami | ||

| + | ** Finish: Drop off CT1 in Boston | ||

| + | |||

| + | * Track B: | ||

| + | ** Start: Pick up CT2 in Atlanta | ||

| + | ** Finish: Drop off CT2 in New York | ||

| + | |||

| + | ===== Load Plan XML for Non Optimal ===== | ||

| + | TBD | ||

| + | |||

| + | ==== TMS use options ==== | ||

| + | |||

| + | * operator creates [[#Optimal route]] manually | ||

| + | ** discovering shipments to combine | ||

| + | ** discovering optimal route | ||

| + | ** discovering optimal cost carrier | ||

| + | |||

| + | * operator creates [[#Non Optimal route]] manually | ||

| + | |||

| + | * operator runs optimization and system suggests [[#Optimal route]] | ||

=== Combining 2 routs into one === | === Combining 2 routs into one === | ||

Revision as of 11:47, 15 September 2010

Contents |

Temp

One CT from A to B

- import/create 1 CT

- move CT from A to B on one truck (manually) (One Load?)

- Assign trucker (manually)

- Assign pickup/delivery dates (manually?)

Two CTs from A to B

- import/create 2 CT

- move both CTs from A to B on one truck (manually) (One Load?)

- Assign trucker (manually)

- Assign pickup/delivery dates (manually?)

Miami to Boston and Atlanta to NY

- CT1:

- from: Miami, FL

- to: Boston, MA

- CT2:

- from: Atlanta, GA

- to: New York, NY

Shipment Import XML

TBD

Optimal route

- Track A:

- Start: Pick up CT1 in Miami

- Stop#1: Pick up CT2 in Atlanta

- Stop#2: Drop off CT2 in New York

- Finish: Drop off CT1 in Boston

Load Plan XML for Optimal

TBD

Non Optimal route

- Track A:

- Start: Pick up CT1 in Miami

- Finish: Drop off CT1 in Boston

- Track B:

- Start: Pick up CT2 in Atlanta

- Finish: Drop off CT2 in New York

Load Plan XML for Non Optimal

TBD

TMS use options

- operator creates #Optimal route manually

- discovering shipments to combine

- discovering optimal route

- discovering optimal cost carrier

- operator creates #Non Optimal route manually

- operator runs optimization and system suggests #Optimal route

Combining 2 routs into one

Pic on page 153 in User guide.

Given:

- CT1: from Miami to Toronto

- CT2: from Atlanta to New York

System should create one load:

- Miami(pick up) to Atlanta (pick up) to New York (drop off) to Toronto (drop off)

Business story

July 22

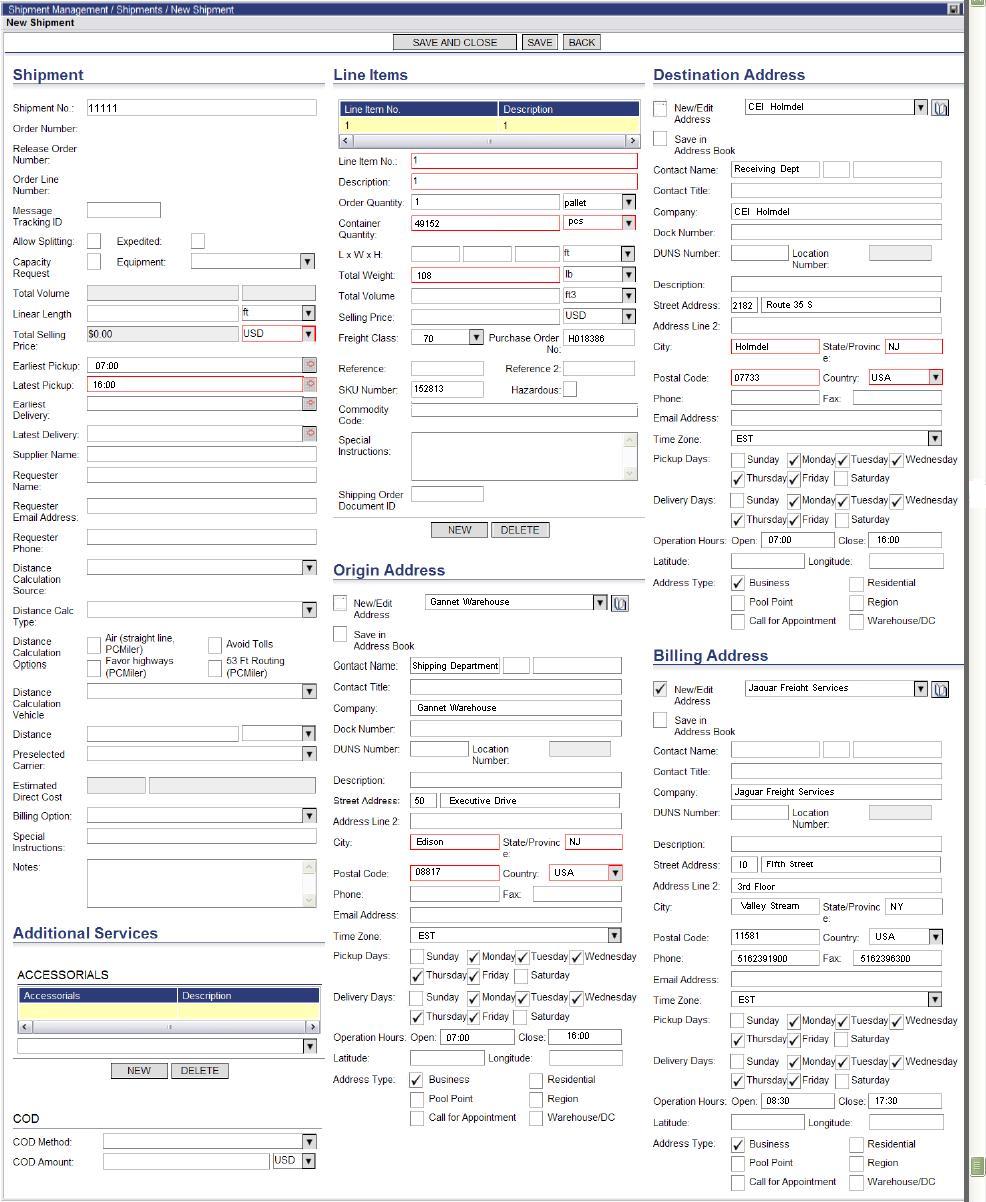

Shipper Mary with Jackel creates 1 new CT record (# 11111) shipping from her NJ warehouse, Gannet Warehouse at 58 Executive Drive in Edison, NJ. She only has 1 pallet ready and would like to get this off of her warehouse dock so her warehouse can continue with their monthly inventory stock report. Now at the same shipper Harry with Princeton Label creates 1 new CT record (# 11145) shipping from his NJ warehouse, Princeton Labels & Packaging Inc at 1226 Route 130 in Robbinsville, NJ. He has about 15 pallets that are ready to ship today and hopes that CEI Roanoke will approve this PO/SKU to ship.

...later that day...

Shipper Orlando with Pochet creates 1 new CT record (# 11200) shipping from his NJ warehouse, Vecco Holdings at 6801 West Side Avenue in North Bergen and he also has only 1 pallet that is ready to ship'

...even later that day...

At once, 2 separate Arden planners approve these 3 CT records (# 11111, 11145 & 11200) and now Jag operator Susan notices that her TDS dashboard has 3 approved shipments. So she logs into TMS and finds those same 3 records on her new shipment list. Its now 3:45 in the afternoon and as Susan reviews each of the shipments, she notices they are all shipping from NJ and arranges in TMS to build a load with the optimization process. After her load is built, she tenders the load to Jewels Transportation and awaits their replies.

...shortly before quitting time...

Jewels accepts the tender, confirms they'll arrange to collect all 3 shipments at 17 pallets total the next day. Now all 3 CT2 records are updated with the pickup truckers name, as well as the estimated pickup date. As well, all 3 shippers, including EA Dom receive an e-mail notification from cybertrax@jaguarfreight.com that their records were approved and Jewels Transportation will pickup.

Late afternoon July 23

Jewels collects all 3 shipments and updates their system. Trucker unloads these shipments at his warehouse and places the 1 shipment to the side for a different carrier to arrange the delivery and updates their system that all were collected and on hand. Once they update their system, that information is sent to TMS, then TMS sends the information to Jaguar and automatically updates the CT records with the actual pickup date.

...early evening

Delivery trucker, Lawrence Trucking goes in to pick up the 1 shipment for CEI Roanoke. He signs a confirmation receipt (which is like a POD) of what he is picking up and gives a copy to Jewels. They update their system that this 1 shipment was transferred to the delivery trucker accordingly and their system sends that information to TMS, then TMS sends the information back to Jaguar and automatically updates the CT record with the delivery truckers name, including the estimated & actual delivery dates. Now Jewels takes the signed confirmation receipt, writes the CT# reference on it (as the CT# must match the CT# that was created by shipper user) and faxes/e-mails the POD to Jaguar Freight.

...shortly after Lawrence leaves Jewels dock

Jewels warehouse manager is arranging for his truckers morning deliveries. He loads his driver with several different shipments delivering to the local NJ area which includes these 2 shipments that are delivering to CEI Holmdel. He updates his system that these 2 shipments will be delivering tomorrow Jul 24 and that information sends to TMS. Then TMS sends the information back to Jaguar and automatically updates the CT record with the delivery truckers name, including the estimated date.

the next morning July 24...

Jag operator Susan receives the Lawrence POD from Jewels and up loads the POD into the CT record. She also checks to see that Jewels has arranged for the 2 shipments to CEI Holmdel for delivery today.

...right before lunch

Jewels dispatcher hears from his local NJ driver who advises he just got a flat tire...He advises him that it's going to take some time before he can get it fixed and is unsure if he can arrange his last drop...His last drop or delivery is for CEI Holmdel. Now Jewels Dispatcher calls Jaguar to notify them of the same and Jaguar advises Debbie at CEI Holmdel that her delivery will be late

4:35 pm...

After some long hours of phone calls and e-mails, the Jewels driver was successful in fixing his flat, as well as delivering these 2 shipments to CEI Holmdel. He calls his dispatcher to advise this and he updates his system that these 2 shipments were delivered today Jul 24. That information is sent to TMS, then TMS sends that same information back to Jaguar and automatically updates the CT record with the actual delivery date.

..whenever the driver returned

Jewels takes the POD (or signed confirmation receipt), makes sure that the CT# is listed on the paperwork and faxes/e-mails the POD to Jaguar Freight.''

the following morning July 25

Jaguar operator received the POD document and uploads it into the CT record.'

Use Cases

Use Case 1.

Jaguar Discovers Approved CTs

Figure 1

Jaguar operator logs into CT2 internal application to find 3 new "Approved" CT records on their TDS dashboard.

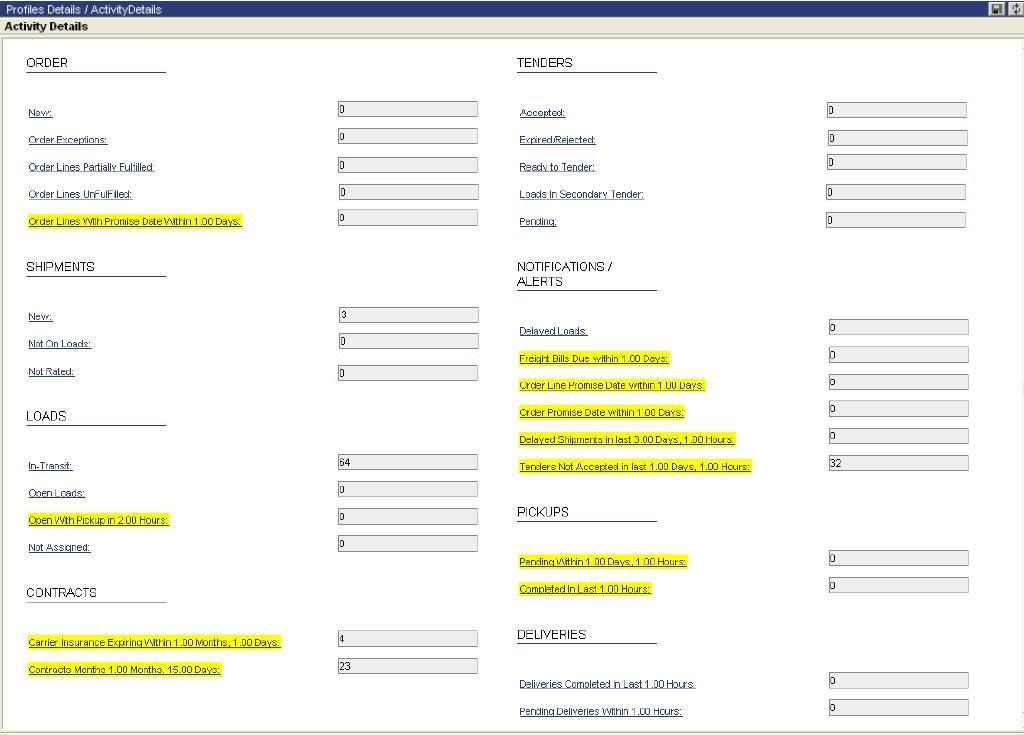

Jaguar Operator uses TMS

Figure 2

Jaguar operator logs onto the TMS system, goes into the Main Menu, > Activity Summaries > Activity Details to find their are new shipments listed. (These are the same "Approved" CT records that are on their TDS dashboard on the internal app).

Figure 3

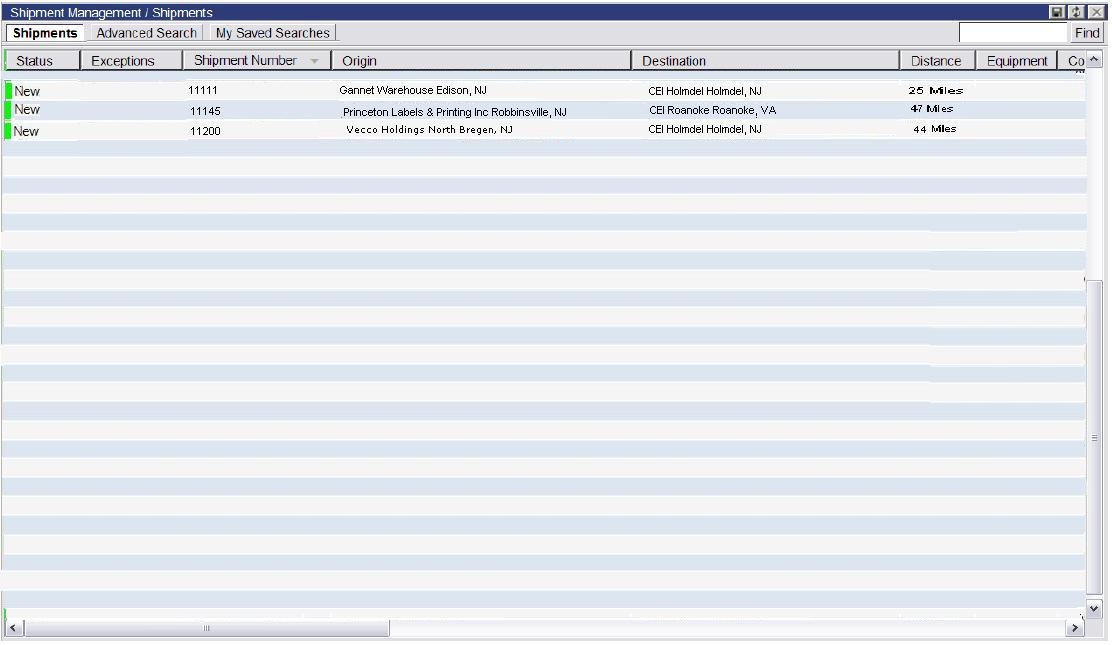

Jag operator clicks on the number of new shipments (3) to review for them to decide who they would like to arrange for the pickup.

Figure 4

Jag operator looks at the first CT record # 11111.

Figure 5

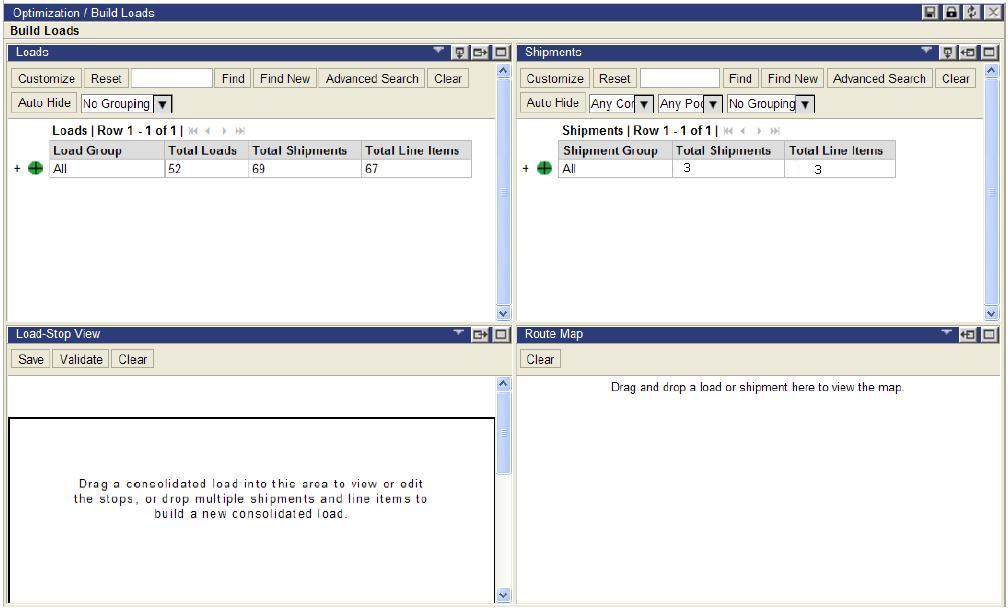

Jaguar operator Susan begins the optimization Process from the new shipment list. She highlights all 3 new shipments, then she right clicks and chooses option Consolidate All. Now the build load page displays.

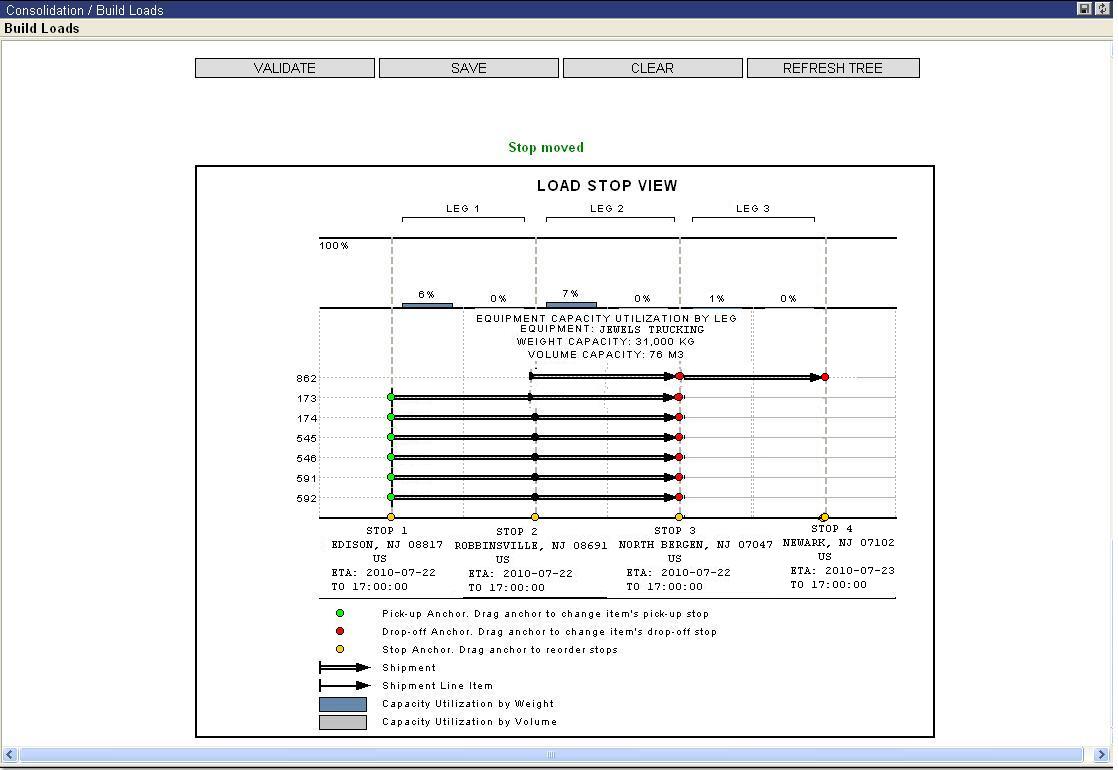

Figure 6

Jaguar operator routes via TMS and uses the Interactive Load Editor to arrange the order of pickups and once done, chooses Validate so she can send a tender to the trucker.

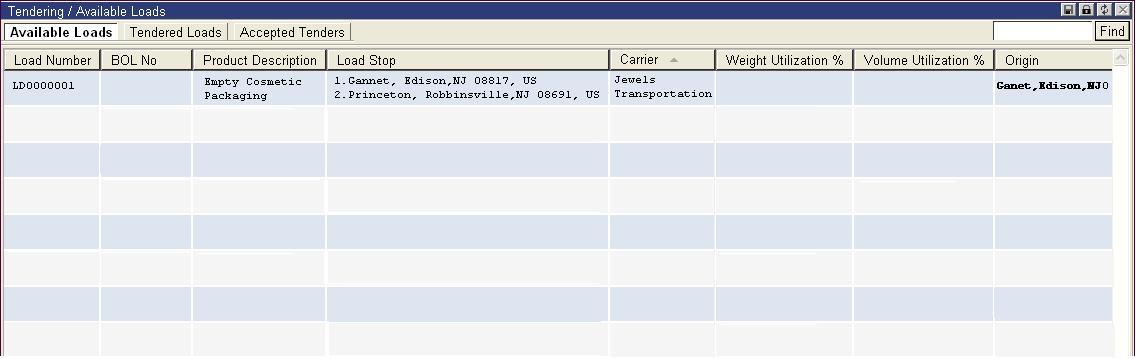

Figure 7

Jaguar operator tenders the load load to Jewels Trucking by right clicking on the load number. TMS transits this information to the pickup truckers system and Jag operator waits for their acceptance or rejection.