Business Process and Use Cases for NATP

From UG

(→Hub and spoke model) |

(→Hub and spoke model) |

||

| Line 14: | Line 14: | ||

== Hub and spoke model == | == Hub and spoke model == | ||

| - | [[ | + | [[http://en.wikipedia.org/wiki/File:Airline_hub-1995.svg]] |

== Transportation == | == Transportation == | ||

Revision as of 18:14, 28 April 2010

Intro

The goal of this article is to describe various workflows (business processes) related to NATP project and related required user interactions with CT2 (use cases).

Ship direct from origin to destination

Aggregate demand across destination and using a milk run from each origin

Aggregate demand across origin and using a milk run from each destination

Ship via Distribution Center

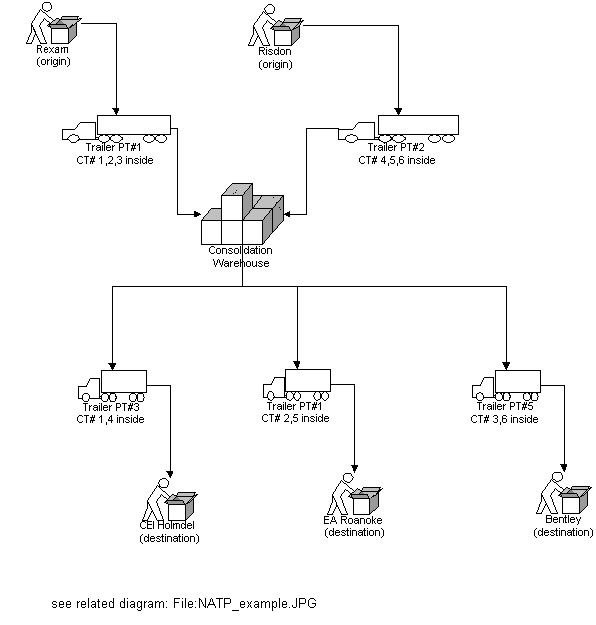

Hub and spoke model

[[1]]

Transportation

Summary

Let's look at the typical example - what might happen.

It is estimated that on an average day about 30 NATP "shipping orders" would come in.

Each order has an info on:

- what to ship (PO, SKU, PCS, Gross weight, etc)

- shipping from info (address)

- shipping to info (address)

In general, for every order CT record would be created.

This order will be forwarded to selected trucking company.

Trucking company handles the order and sends back PODs.

Operator also would:

- generate reports (for example In Transit)

- do billing

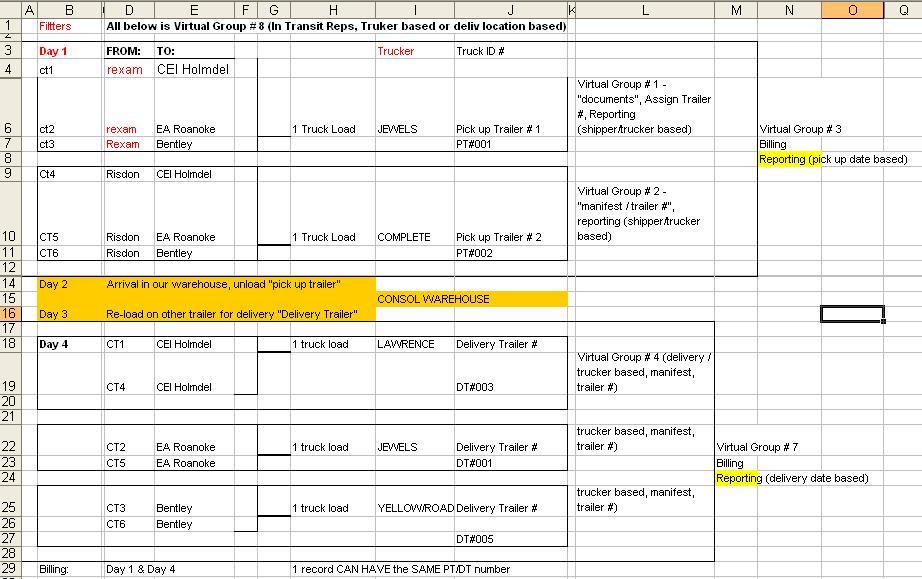

Six Shipments Example

This is a typical example that we are looking at in details.

Day 1

Assume for simplicity sake that only 6 orders came in that day.

CT 1,2,3,4,5,6 were created.

See #Figure 1.

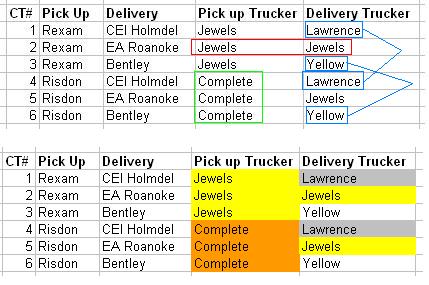

As you can see CT 1,2,3 are to be picked up at Rexam and CT 4,5,6 at Risdon.

If you observe orders further you will see that 6 CT's share only 3 delivery locations: {CEI Holmdel, EA Roanoke and Bentley}

In this case 2 trucks were used to pick up these 6 CTs. They all delivered to Consol Warehouse.

Day 2

Truck Loads PT# 1 and 2 were unloaded.

Day 3

Truck Loads DT# 3,4,5 and 2 were loaded onto 3 Trucks. Each truck is designated to one of 3 locations.

Day 4

Trucks deliver goods from Consol Warehouse to destinations.

Transportation Alternatives

Note: more info on this will be published here: TMS features (NATP)

- Is it possible that truck would take additional trips to pick up additional non-Jaguar cargo?

- Yes?

- Theoretically it is possible for one truck to pick up from multiple locations before delivering to warehouse

- Are we going to have this case in NATP?

- Theoretically it is possible for one truck deliver to multiple locations (goods from warehouse)

- Are we going to have this case in NATP?

- Theoretically it is possible for one truck to pick up and deliver bypassing warehouse (single pick up and/or delivery)

- Are we going to have this case in NATP?

- Theoretically it is possible for one truck to pick up and deliver bypassing warehouse (multiple pick up and/or delivery)

- Are we going to have this case in NATP?

Reporting

Documentation

Billing

Different billing models are possible. We describe only one here.

Purchase

As in ATP Jaguar will generate Trucking Billing Manifest for each individual trucking company.

Charges from trucking vendors will come next day

Sales

All NATP shipments have one Client EO.

Create one Sales invoice per group of CTs booked/created on day X.

In #Six Shipments Example this group would consist of CT 1,2,3,4,5,6.

As in Business Process for Arden Trucking Domestic sales invoice will consists of:

- Trucking Billing Manifest - detailed charges per CT; it is based on vendor charges (pick up and delivery)

- Pdf invoice with a sum of all charges for a group (could be actually 2 numbers representing various charge codes)

Additional invoice is possible covering special charges.

See also

- Business Process for Arden Trucking Domestic - another trucking domestic work flow (currently in use)