Vendor Inventory

From UG

(→CBN: Core Business Need) |

(→Notes from Systems Architect) |

||

| Line 19: | Line 19: | ||

=== Notes from Systems Architect === | === Notes from Systems Architect === | ||

| - | Core | + | Core goal of this system I feel is the following: ''for any selected SKU EA planner will be able to see: where and how many (much) of this commodity is stocked (and in transit) in all locations across the globe. Some additional detailed information (example: mode of transport for "in transit stock") and aggregated statistic (example: US total stock vs International total stock) will be provided'' |

To achieve the above information about each SKU must be created and updated accurately and timely. | To achieve the above information about each SKU must be created and updated accurately and timely. | ||

Revision as of 03:46, 27 May 2010

Info

- Scope: This wiki defines CT2 component.

- Parent Mantis: http://mantis.jaguarfreight.com/mantis/view.php?id=1598

- Related Concepts and Glossary:

CBN: Core Business Need

This wiki section is managed by: Module Owner

Elizabeth Arden would like to have a Vendor Inventory module that can track SKUs that are on hand by vendors, in-transit, and on hand by external manufacturers to help the inventory planner process an order shipment plan (Tira).

Notes from Systems Architect

Core goal of this system I feel is the following: for any selected SKU EA planner will be able to see: where and how many (much) of this commodity is stocked (and in transit) in all locations across the globe. Some additional detailed information (example: mode of transport for "in transit stock") and aggregated statistic (example: US total stock vs International total stock) will be provided

To achieve the above information about each SKU must be created and updated accurately and timely.

Some notes/questions:

- Are we planning to manage all SKUs including WIP?

- I assume not too many SKUs are added every week. This means that for data entry SKUs should be selected not entered by end user. Entered only by admin.

- If at least one vendor is not entering/updating numbers (for given SKU) in the system then all numbers (for this SKU) will be incorrect

- When some quantity of given SKU moves from (sending) stock point sSP to (receiving) stock point rSP system must be notified of this stock transaction. Ideally we should follow the following steps (example) - see #Example A

Example A

- [pull model]

- TBD

- [push model with authorization]

- Sending stock point ABC Inc (in City A) sends request to Approval Party: "wishing to release" "quantity 100 of SKU#123";

- waiting until it is approved

- approval comes

- Carrier Jaguar notified: "requesting the move with given time frame"

- Carrier selects Mode of Transport into system

- Carrier ready to move, requests appointment for date/time

- ABC confirms appointment

- Carrier sends trucks to pick up

- trucks arrive, load, depart

- a) Sending stock point ABC Inc (in City A) notifies System that it released "quantity 100 of SKU#123" to Carrier Jaguar at this time/date

- b) Carrier Jaguar confirms that it received "quantity 100 of SKU#123"

- If a) and b) match then system reduces inventory level at ABC Inc (in City A) and increases level at Jaguar of SKU#123 by 100. Else generate Error.

- c) Carrier Jaguar notifies that it delivered "quantity 100 of SKU#123" to Receiving stock point XYZ Inc (in City B)

- d) Receiving stock point XYZ Inc (in City B) notifies that it received "quantity 100 of SKU#123"

- If a) and b) match then System reduces inventory level at Jaguar and increases inventory level at XYZ Inc (in City B) of SKU#123 by 100. Else generate Error.

Please note that for "update inventory transaction" both sending and receiving stock points must send accurate information that match.

If it does not match (example: Jaguar submitted infor that it delivered 100 but XYZ claims they received only 99) then system will generate Error message that has to be resolved by System Admin.

BR: Business Requirements and Design Ideas

SD: Systems Design and Prototype

System Requirements

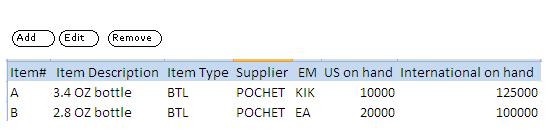

- A portal for vendor to enter/update info for Inventory

- Vendor's visibility

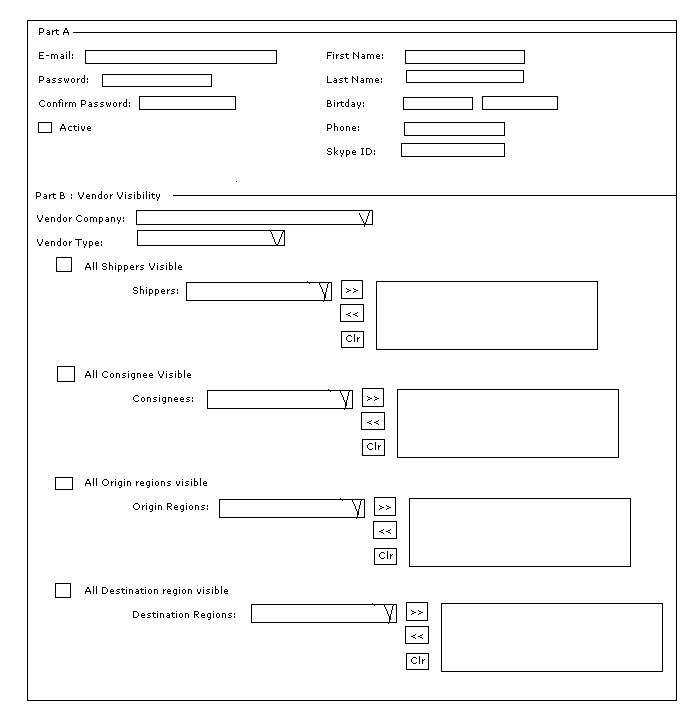

- Admin: Vendor Users

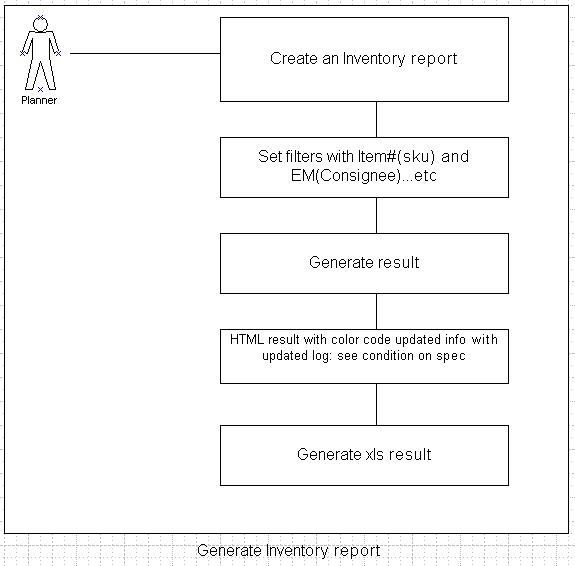

- Inventory Report for Elizabeth Arden Planner

- Filters:

- Item#

- Supplier

- EM(External Manufacturer)

- Result: HTML and xls

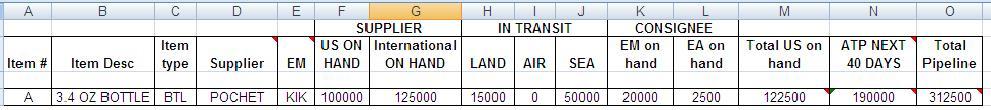

- Item#

- Item Desc

- Item type

- Supplier

- EM(External Manufacturer)

- US on hand

- International on hand

- In-transit - Land (truck mode)

- In-transit - Air (Air mode)

- In-transit - Sea (Ocean mode)

- EM on hand

- EA on hand

- Filters:

- Update log for updated information by vendor's users

- Column heading color code:

- Column updated in the last 7 days - green (need to confirm with Simon)

- Column updated in the last 15 days - yellow (need to confirm with Simon)

- Column not updated in the last 30 days - red (need to confirm with Simon)

- pop-up window for detail updated info

- Updated by: user profile (vendor)

- Updated date: dd- mon -yyyy

- Detail updated: From last transaction to updated transaction information

- Column heading color code:

Steps

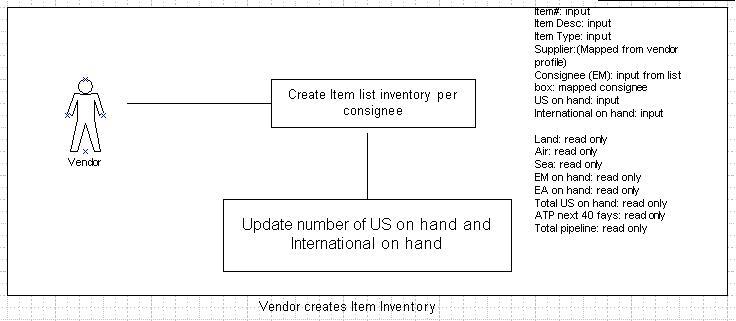

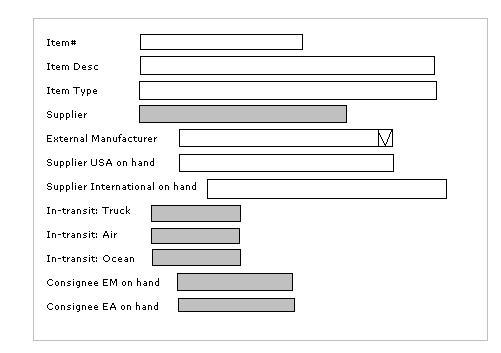

Step 1

- Vendor logs on to Internal application

- Require: Vendor visibility (limited access to module and visibility for vendor company)

- Vendor logs on to the Inventory module

- Vendor's visibility: A vendor can only add, update, and view their specific inventory

- For example, vendor A logs on to the system, vendor A can only see inventory that belongs to vendor A.

- See #Figure 8. View page - Vendor Inventory

- Vendor's visibility: A vendor can only add, update, and view their specific inventory

- Vendor adds:

- Item#

- Item Desc

- Item Type

- Supplier (read only vendor name, mapped from vendor user's profile)

- External Manufacturer (EM)

- Supplier USA on hand

- Supplier International on hand

- NOTE: the combination of Item# and EM are unique

- System auto-calculates:

- If supplier USA on hand number X is added, then number X is added to Total US on hand

- If supplier International on hand number Y is added, then number Y is added to ATP next 40 days

- Total pipeline = Total US on hand + ATP next 40 days

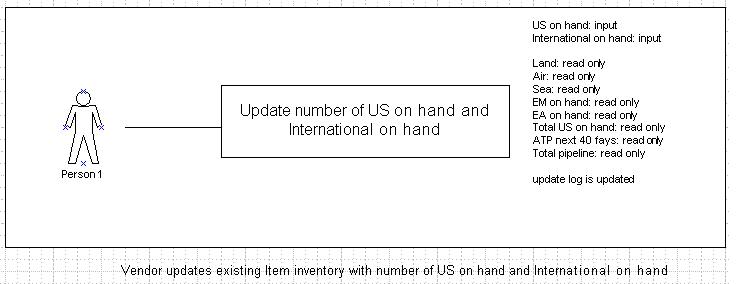

Step 2

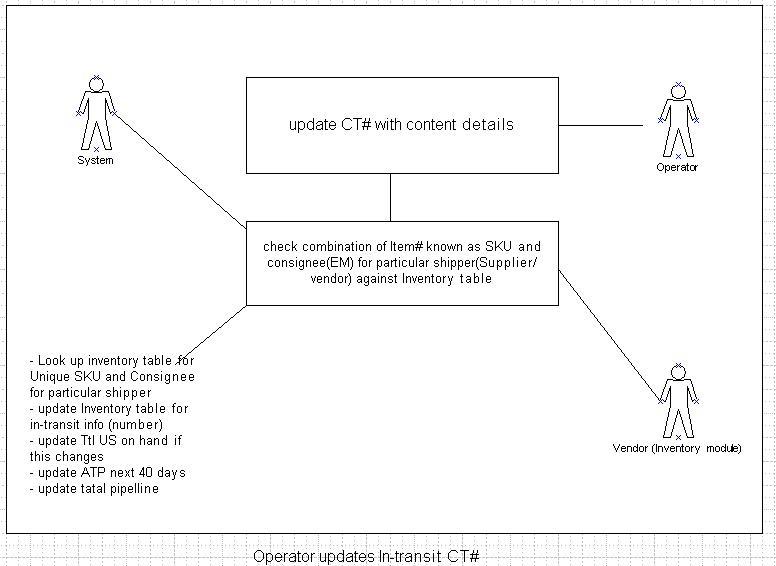

- Jaguar operator creates a record from Ops module with all information that consider a shipment as in-transit time (moved but not delivered)

- Shipper (supplier)

- Consignee (EM)

- MOT

- Item#

- Item Desc

- Qty

- The combination of Item# and EM are unique (this info will be checked against Vendor Inventory table in order for system to auto-update info for Inventory information)

- Process of behavior between JG operator updates a shipment with needed information and Inventory module

- If a combination of shipper and consignee are a part of Vendor Inventory table, it should be tagged on ContTab that some items are a part of Inventory

- Then try to search commodity table

- Vendor Inventory table is running in the background that

- Select MOT, Qty value from commodity table where consignee = " " and SKU# = " "

- Update Vendor Inventory table

- If MOT is Truck update qty value -> LAND

- If MOT Land qty value A is added, then value A is added to ATP Next 40 days field

- If MOT is AIR update qty value -> AIR

- If MOT Air qty value B is added, then value B is added to ATP Next 40 days field

- If MOT is Ocean update qty value -> SEA

- If MOT Sea qty value C is added, then value C is added to ATP Next 40 days field

- Total pipeline = Total US on hand + ATP next 40 days

- If MOT is Truck update qty value -> LAND

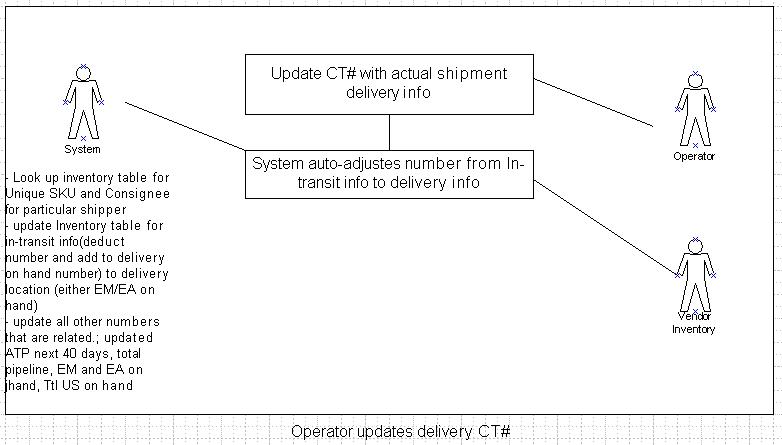

Step 3

- Jaguar Operator updates the shipment's actual delivery date (no longer in-transit)

- Once the shipment is delivered to destination (consignee/EM)

- System run in the background updating the Inventory table

- The shipment moved and delivered, that means quantity of this shipment is delivered to consignee and no longer In-transit - quantity value will be added to consignee on hand (EM/EA on hand)

- Number of qty value from a particular in-transit MOT shipment will be deducted from in-transit MOT and added to EM on hand and deducted from ATP Next 40 days field

- If EM(consignee) is Elizabeth Arden, this quantity value will be deducted from in-transit MOT and added to EA on hand and deducted from ATP Next 40 days field

- For example, if 5000 of item# A from POCHET(supplier or shipper) is on in-transit AIR to KIK(EM or consignee), 5000 will be added to AIR, but once it is deliver to KIK, 5000 from AIR will be deducted and added to EM on hand (KIK on hand)

- If EM on hand number Z is added, then number Z will be added to Total US on hand

- Total pipeline = Total US on hand + ATP next 40 days

NOTE:

- Total pipeline is always the same when deducting in-transit quantity to adding it to EM on hand

- Total US on hand: Number of Supplier US on hand + Number of Consignee EM on hand + Number of Consignee EA on hand

- ATP next 40 days: Number of Supplier International on hand + Number of In-transit LAND + Number of In-transit AIR + Number of In-transit SEA (available to promise on Inventory module)

- Total pipeline : US Total on hand + ATP next 40 days on Inventory module

- See #Figure 1. Vendor Inventory

- See use cases figures below

Design

Filters

Item#

- Label:

- Widget:

- Mapping:

- NOTE:

Supplier

- Label:

- Widget:

- Mapping:

- NOTE:

EM(External Manufacturer)

- Label:

- Widget:

- Mapping:

- NOTE:

Fields

Item#

- Label: Item#

- Type: Datatypes#ascii

- Widget: textbox

- Size: TBD

- Note: Known as Commodity#SKU

Item Desc

- Label: Item Desc

- Type: Datatypes#ascii

- Widget: textbox

- Size: TBD

- Note: Known as Commodity#Description

Item type

- Label: Item Type

- Type: Datatypes#alphanumeric

- Widget: textbox

- Size: TBD

- Note: New field (this is straightforward for Item Type such as BTL(bottle))

Supplier

- Label:Supplier

- Type: read only field Datatypes#ascii

- Widget: textbox

- Size: TBD

- Mapping: from vendor's user profileCt#Shipper

- Note: Known as Vendor

EM(External Manufacturer)

- Label:EM

- Type: Datatypes#ascii

- Widget: Listbox

- Size: TBD

- Mapping: Ct#Consignee

- Note: Known as Consignee

US on hand

- Label: US on hand

- Type: Datatypes#positive_integer

- Widget: textbox

- Note: quantity of items that has been shipped and received at US destination

International on hand

- Label: International on hand

- Type: Datatypes#positive_integer

- Widget: textbox

- Size: TBD

- Note: quantity of items that has been shipped and received at International destination other than the US

In-transit - Land (truck mode)

- Label: Land

- Type: Datatypes#positive_integer

- Widget: textbox

- Size: TBD

- Note: quantity of items that has been shipped by truck but not been received at the destination (still on the move)

In-transit - Air (Air mode)

- Label: Air

- Type: Datatypes#positive_integer

- Widget: textbox

- Size: TBD

- Note: quantity of items that has been shipped by truck but not been received at the destination (still on the move)

In-transit - Sea (Ocean mode)

- Label: Sea

- Type: Datatypes#positive_integer

- Widget: textbox

- Size: TBD

- Note: quantity of items that has been shipped by ocean but not been received at the destination (still on the move)

EM on hand

- Label: EM on hand

- Type: Datatypes#positive_integer

- Widget: textbox

- Size: TBD

- Note: quantity of items that has been shipped and received at external manufacturer (known as consignee)

EA on hand

- Label: EA on hand

- Type: Datatypes#positive_integer

- Widget: textbox

- Size: TBD

- Note: quantity of items that has been shipped and received at Elizabeth Arden warehouse

Figures

Figure 1. Vendor Inventory

Figure 2. Vendor Creates Item Inventory

Figure 3. Vendor Updates an existing Item Inventory for specific EM

Figure 4. Operator updates CT# with in-transit info

Figure 5. Operator updates CT# with delivery info

Figure 6. Create an Inventory report

Figure 7. Add - Vendor Inventory

Figure 8. View page - Vendor Inventory

Figure 9. Admin - Vendor Users

History

m.....

- http://mantis.jaguarfreight.com/mantis/view.php?id=...

- In Production

BA ...

- ...

- final version: ...