Requirements for EDI to TMS

From UG

(Difference between revisions)

(→High level view of Workflow) |

(→About) |

||

| Line 3: | Line 3: | ||

== About == | == About == | ||

This is a Analysis / Requirements wiki for EDI to TMS proj | This is a Analysis / Requirements wiki for EDI to TMS proj | ||

| + | |||

| + | == Glossary == | ||

| + | |||

| + | '''IP''' - Integration Point | ||

== Introduction == | == Introduction == | ||

Revision as of 16:55, 19 July 2010

Contents |

About

This is a Analysis / Requirements wiki for EDI to TMS proj

Glossary

IP - Integration Point

Introduction

Core Business Need: Jaguar needs ability to optimize truck domestic shipments:

- create optimal loads, cost, routs, etc

- automate tariffs, communication with carriers

Above features are normally present in TMS software.

To achieve that it was decided:

- buy and use existing TMS solution (phase 1) - this project

- gradually add these features to CT2 (phase 2) - another project

To complete phase 1 we need to implement:

Vendor evaluation

Currently there are 2 systems we are considering:

- from Descartes

- from Lean Logistics

Functionality Overview

In a nutshell:

- shipment record will be created in CT2 and forwarded to TMS through EDI

- in TMS Jag oper will run optimizations

- TMS sens bids to carriers

- one carrier accepts the bid and start moving shipments

- carrier submits updates into TMS (example: actual pickup date)

- update above will be forwarded into CT2 through EDI

See also Integration Points.pdf attached to 2183.

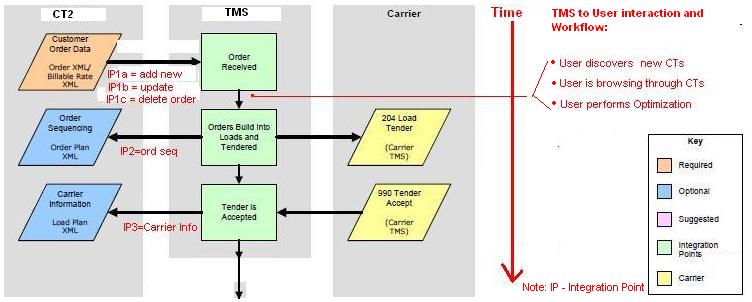

See Figure below:

Figure Integration Points

Workflow

High level view of Workflow

- Numbers of CTs gets approved by CT2 Planner user

- CT2 sends info about these CTs to TMS (IP1)

- discover them in TMS

- browse them in TMS

- "route" them in TMS

- option 1: use optimization module

- option 2: manually optimize